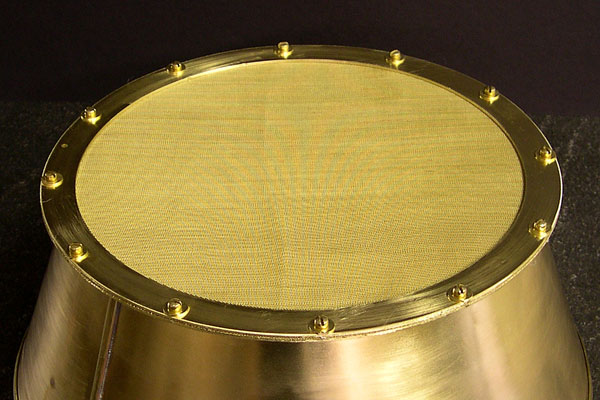

Brass Sieve

|

Every once in a while a job comes along that is just a

little bit different from the normal line of work. This is one

of them. A request for these sieves came from the United States

Department of Agriculture Plant Protection and Quarantine office

in the Finger Lakes region of New York State. The sieves that

were in use were old and the screen material was showing severe

signs of wear. New sieves were constructed completely from brass

and they were made so that the screens could be changed when

necessary.

The need for the sieves is interesting. Many years ago

some of the potato crop fields in New York State were found to

be infested with potato cyst nematodes that feed off of the potato

root and caused severe reductions in yield. Since it is virtually

impossible to eradicate this pest, the infected land has been

placed under quarantine to prevent the spread of the nematode.

All of Long Island and portions of a number of counties in the

upstate New York Finger Lakes region are currently under quarantine.

It is the job of the USDA to make sure that proper measures are

taken to insure that the problem does not spread. This work includes

disinfection of farm equipment as well as taking numerous soil

samples that must be tested for the presence of the nematodes.

This is where the sieves come into play. The soil samples

are turned into a slurry of water and soil which is poured through

a series of sieves that have progressively smaller openings in

the screen material. Since the nematodes are large enough to

be seen with the naked eye it is possible to check for their

presence on the last sieve of the progression. It is interesting

to note that while I was working on these sieves in April, 2006

a similar potato cyst nematode was discovered in a field in Idaho.

This was of considerable concern since growers in the Pacific

Northwest account for over 60% of the US fall potato production.

The yield from Idaho growers accounts for approximately one-third

of that total.

The body of the sieve has been soldered to one of two heavy

gauge brass rings; the

screen material is sandwiched between the two rings.

|

|